Aluminum panels' lightweight yet delicate nature poses unique challenges for PDR due to their thin composition and susceptibility to dents. Specialized tools and techniques tailored for aluminum are crucial for collision repair technicians to successfully address these vulnerabilities, ensuring precise repairs without damaging aesthetics. Advanced methods like precise dent pulling tools offer an effective, cost-efficient, and environmentally friendly alternative to conventional paint repair for minor damages on luxury vehicles.

Aluminum panels, popular for their lightweight yet durable properties, have become a preferred choice in various industries. However, their unique composition presents distinct challenges during the Panel Damage Repair (PDR) process. This article explores why traditional PDR techniques may not suffice for aluminum surfaces and highlights specialized methods that ensure efficient and effective repairs. By understanding the vulnerabilities of aluminum panels, technicians can employ tailored strategies to restore their integrity and aesthetics, catering specifically to the needs of this modern material.

- Understanding Aluminum Panel Composition and Vulnerabilities

- Challenges in Traditional PDR for Aluminum Surfaces

- Specialized Techniques for Efficient and Effective PDR on Aluminum Panels

Understanding Aluminum Panel Composition and Vulnerabilities

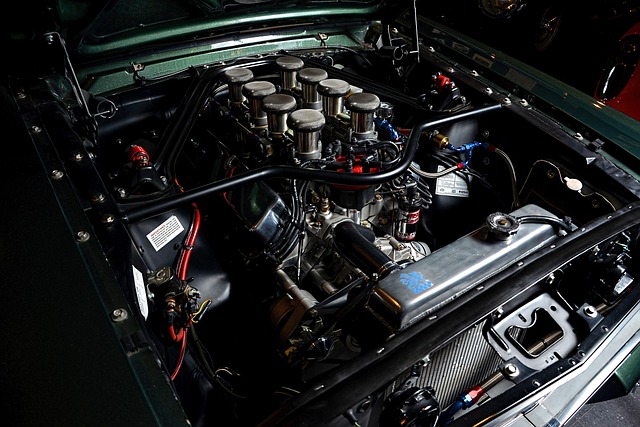

Aluminum panels, while lightweight and durable, present unique challenges when it comes to PDR for aluminum panels (i.e., paintless dent repair). Composed primarily of aluminum alloy, these panels are susceptible to specific types of damage, including dents, dings, and creases. Unlike steel panels, which have a more flexible and forgiving nature, aluminum panels are relatively thin and tend to hold their shape after impact, making dent removal more complex. The metal’s inherent properties, such as its malleability and reactivity to oxidation, also affect the repair process.

In a collision repair shop, technicians must be adept at identifying and addressing these vulnerabilities. Aluminum panel damage often requires specialized tools and techniques tailored for this specific material. Standard dent removal methods may not be effective, leading to unsightly repairs or permanent marks if not handled correctly. Therefore, understanding the composition and vulnerabilities of aluminum panels is crucial for successful car damage repair, ensuring that any dent removal technique employed aligns with the unique characteristics of these modern automotive components.

Challenges in Traditional PDR for Aluminum Surfaces

Aluminum panels present unique challenges when it comes to traditional PDR (Paintless Dent Repair) techniques. Unlike steel, which is more resilient and flexible, aluminum is a lightweight metal with a lower tensile strength, making it more prone to damage during the repair process if not handled correctly. The metallic properties of aluminum also mean that dents tend to appear as shallow indentations or even as surface deformities, which can be particularly difficult to rectify without leaving visible traces.

Moreover, many luxury vehicle repairs involve intricate and precise panel designs, where even the slightest misstep in PDR can result in unsightly aesthetics. As such, automotive technicians specializing in PDR for aluminum panels require advanced skills and specialized tools to address these challenges effectively. This involves understanding the unique characteristics of aluminum, mastering precision techniques, and employing modern equipment designed specifically for its delicate nature, ensuring top-tier vehicle repair services are delivered without compromising the original appearance and value of the luxury vehicles.

Specialized Techniques for Efficient and Effective PDR on Aluminum Panels

Specialized techniques are essential for efficient and effective PDR (Paintless Dent Repair) on aluminum panels. Unlike traditional metal, aluminum is a softer, more malleable material that requires unique approaches to restore its original condition. Professional technicians use advanced tools and methods tailored for aluminum’s specific properties. These include specialized dent pulling tools designed to apply precise pressure without damaging the panel or underlying structure.

The process involves careful assessment of the damage, followed by strategic placement of the tools to gently work out the dents. This meticulous approach ensures that the aluminum panel returns to its original shape and smoothness, maintaining the vehicle’s overall aesthetics. As a result, PDR for aluminum panels offers an effective alternative to conventional paint repair methods, providing auto owners with a cost-efficient and environmentally friendly solution for minor damage, such as door dings and hail marks, without sacrificing the car’s overall look in popular choices like vehicle restoration or car paint repair.

Aluminum panels present unique challenges in Paint Damage Repair (PDR) due to their composition and vulnerabilities. Understanding these aspects is crucial for efficient and effective repair. By employing specialized techniques tailored for aluminum, professionals can ensure superior results while addressing the specific needs of these surfaces. These advanced methods revolutionize PDR, allowing for quick and lasting fixes, catering to the growing demand for reliable restoration in today’s automotive industry.