TL;DR:

Paintless Dent Repair (PDR) for aluminum automotive bodywork is a specialized, cost-effective technique that preserves original finishes. It involves meticulous inspection, gentle dent removal using tools like rubber mallets, and strict adherence to safety measures due to aluminum's conductivity. Safety gear, proper ventilation, static discharge suppression, and specialized PDR tools are crucial. Best practices include thorough cleaning, use of aluminum-specific tools, precise pressure application, and regular technician training for high-quality, risk-mitigated repairs that maintain vehicle values in a competitive market.

“In today’s automotive industry, PDR (Paintless Dent Repair) for aluminum panels has emerged as a game-changer in vehicle restoration. As aluminum becomes the preferred material for car manufacturing, understanding the safety considerations of this process is paramount. This article delves into the intricacies of PDR for aluminum panels, exploring key safety precautions, essential equipment, and best practices to mitigate risks effectively. By embracing these guidelines, professionals can ensure safe and quality repairs.”

- Understanding PDR for Aluminum Panels: An Overview of the Process

- Key Safety Precautions and Equipment in PDR for Aluminum Panels

- Best Practices for Mitigating Risks During PDR for Aluminum Panel Repairs

Understanding PDR for Aluminum Panels: An Overview of the Process

PDR for aluminum panels, short for Paintless Dent Repair, is a specialized technique used to restore and fix dents and dings on automotive aluminum bodywork. Unlike traditional auto frame repair methods that often involve sandblasting, painting, or replacing damaged parts, PDR is a non-invasive process. It leverages advanced tools and techniques to gently push out dents from the surface of the panel without damaging the original finish. This method not only preserves the car’s aesthetic appeal but also significantly reduces restoration time and costs compared to conventional vehicle restoration techniques.

The PDR process begins with careful inspection to identify the extent of damage. Special tools, such as rubber mallets and plastic tools, are then used to gently work the dent back into place. This requires precision and skill to avoid marring or deforming the panel further. Once the dent is removed, the area is thoroughly examined for any hidden damage, ensuring that every aspect of the car’s bodywork, from the exterior surface to underlying panels, is in optimal condition. This meticulous approach makes PDR a preferred choice for those seeking high-quality auto bodywork solutions without the need for extensive repainting or replacement parts, thus keeping car values higher in the ever-competitive automotive market.

Key Safety Precautions and Equipment in PDR for Aluminum Panels

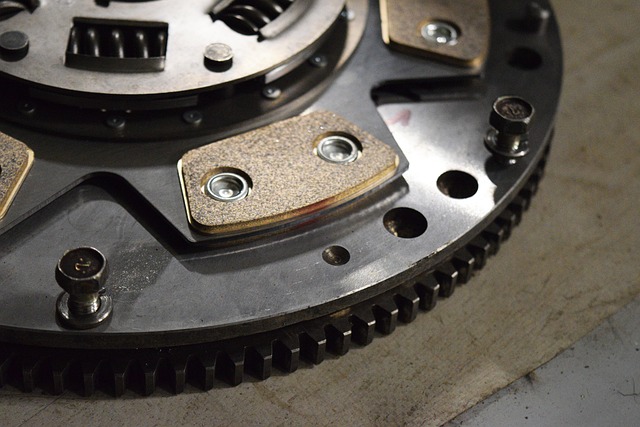

When performing PDR (Paintless Dent Repair) on aluminum panels, safety is paramount to prevent damage to both the vehicle and the technician. Key precautions include ensuring proper ventilation due to the potential volatile fumes from solvents and utilizing protective gear such as gloves, safety glasses, and a respirator mask. Aluminum is known for its conductivity, so static discharge suppression equipment is essential to prevent damage caused by sparks during the repair process.

Specialized tools designed for PDR on aluminum are crucial. These include dent pullers, tab tools, and foam rollers. High-quality equipment ensures precision and efficiency while minimizing the risk of scratches or other surface imperfections. Regular maintenance and calibration of these tools further enhance safety in an automotive body shop or auto collision repair facility, ensuring that every PDR job is conducted safely and effectively for optimal auto repair services.

Best Practices for Mitigating Risks During PDR for Aluminum Panel Repairs

When performing PDR (Paintless Dent Repair) on aluminum panels, adhering to best practices is paramount to mitigate risks and ensure successful repairs. Begin by thoroughly inspecting the panel and dent to understand its severity and identify any potential hidden damage. Proper preparation includes cleaning the area with a suitable cleaner and degreaser, as contaminants can hinder adhesion.

Using the right tools designed specifically for aluminum is crucial. This involves selecting the appropriate pliers, picks, and air guns to avoid marring or damaging the panel. Technicians should also wear protective gear, including gloves, safety glasses, and earplugs, to safeguard against any potential hazards. Consistent pressure and precise techniques are key; excessive force can lead to metal deformation or even cracking. Regular training and familiarity with the PDR process for aluminum panels contribute significantly to minimizing risks during repairs, ultimately enhancing the quality of auto bodywork.

PDR for aluminum panels offers a safe and effective repair method when properly executed. By understanding the process, adhering to key safety precautions, and implementing best practices, professionals can effectively mitigate risks associated with PDR on aluminum panels. These measures ensure not only high-quality repairs but also the well-being of technicians and the preservation of the metal’s integrity.