PDR (Paintless Dent Repair) is a specialized technique that uses advanced tools and trained technicians to repair dents on aluminum car panels without harming the surrounding paintwork. It's an eco-friendly choice, preserving the factory finish, minimizing waste, and reducing the carbon footprint compared to traditional methods like sandblasting or cutting. PDR offers seamless repairs that are hard to distinguish from original panels, appealing to both vehicle restoration enthusiasts and car owners seeking prompt dent removal while maintaining their vehicle’s aesthetic value. For lightweight aluminum vehicles, PDR provides precise repairs that maintain structural integrity while restoring the original appearance, making it a versatile and cost-effective alternative to full paint jobs.

In today’s eco-conscious world, finding sustainable solutions for vehicle repairs is essential. One such method gaining popularity is Paintless Damage Repair (PDR) for aluminum panels. This article explores an innovative and environmentally friendly approach to fixing dings, scratches, and dents on aluminum car bodies using PDR techniques. We’ll delve into the benefits of PDR, provide a step-by-step guide to its application, and highlight why it’s a smart choice for both repairers and vehicle owners, offering advantages in terms of efficiency, cost-effectiveness, and sustainability.

- Understanding PDR and Its Benefits for Aluminum Repairs

- The Process of PDR on Aluminum Panels: Step-by-Step Guide

- Advantages and Applications: Why Choose Eco-Friendly PDR?

Understanding PDR and Its Benefits for Aluminum Repairs

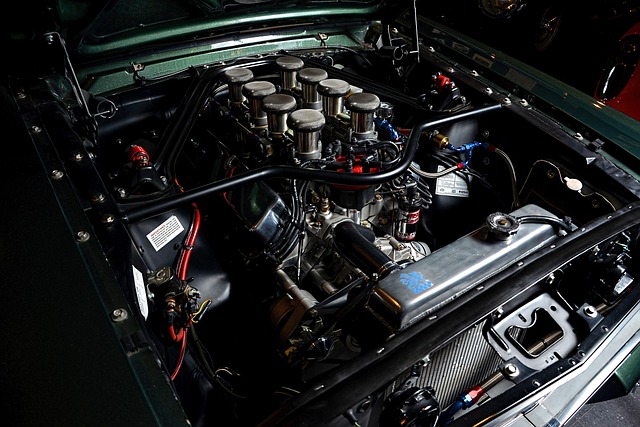

PDR, or Paintless Dent Repair, is a specialized technique that has revolutionized the way we address dents and dings on automotive surfaces, including aluminum panels. This non-invasive method involves the use of specialized tools and trained technicians to gently press and pull damaged areas back into their original shape without damaging the surrounding paintwork. For aluminum repairs, PDR offers numerous advantages. Aluminum is a lightweight yet durable material commonly used in modern vehicle construction, but it’s also prone to dents and scratches. Traditional repair methods often involve sandblasting or cutting, which can be time-consuming and may compromise the integrity of the panel. PDR, however, preserves the original factory finish and structural integrity by eliminating the need for such aggressive techniques.

By opting for PDR for aluminum panels, car body shops provide eco-friendly auto body services that minimize waste and reduce the carbon footprint associated with standard repair processes. This method not only conserves resources but also ensures a sleek, seamless repair that is hard to distinguish from the original panel. For vehicle restoration enthusiasts or those seeking prompt and effective dent removal without leaving visible traces, PDR offers an ideal solution, making it a preferred choice for many car owners and the go-to option for professional vehicle restoration.

The Process of PDR on Aluminum Panels: Step-by-Step Guide

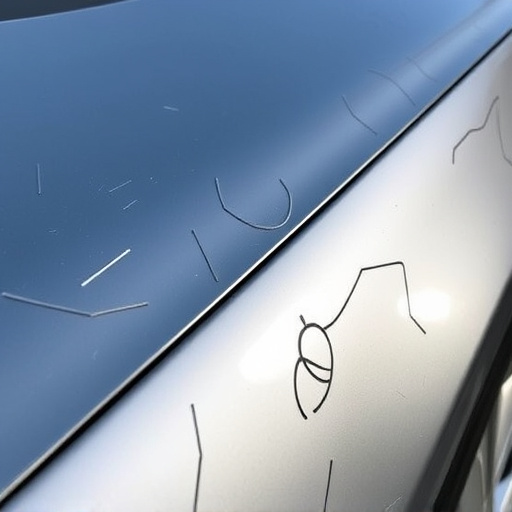

PDR (Paintless Dent Repair) is a specialized technique designed for repairing dents and scratches on aluminum panels, offering an eco-friendly solution for car owners. The process involves several steps to ensure minimal disruption to the original finish. First, the technician inspects the damage to determine the scope of the repair. Next, they prepare the surface by cleaning and drying the aluminum panel. Using a variety of tools, such as dent pullers and tampers, the technician carefully manipulates the metal to push dents back into place without damaging the surrounding area or painting.

Once the dent is removed, the technician may use a special compound to blend any remaining marks, ensuring a smooth and even surface. The final step involves polishing the panel to restore its original luster. This method is particularly effective for minor dents and scratches, providing an efficient and cost-effective alternative to traditional car paint services, especially for bumper repairs or other cosmetic damage.

Advantages and Applications: Why Choose Eco-Friendly PDR?

Choosing eco-friendly PDR (Paintless Dent Repair) for aluminum panels offers a range of advantages that make it an attractive option for both vehicle owners and automotive body shops. Firstly, it minimizes environmental impact by reducing waste and eliminating the need for harsh chemicals or toxic paints, making it a sustainable choice. This method is particularly beneficial for aluminum, which is lightweight and widely used in modern vehicle construction but can be challenging to repair traditionally due to its soft metal nature.

PDR for aluminum panels allows for precise, meticulous repairs that restore the vehicle’s original appearance without compromising structural integrity. It’s versatile; suitable for various types of dents, dings, and scratches, making it a cost-effective alternative to complete vehicle paint jobs or extensive body work. Many automotive body shops are adopting PDR as a game-changer in vehicle restoration, catering to environmentally conscious consumers who seek eco-friendly solutions without sacrificing quality repairs.

PDR for aluminum panel repairs offers a sustainable and effective solution, minimizing waste and environmental impact. By adopting eco-friendly practices with PDR, we can ensure that vehicle damage is repaired efficiently while preserving our planet’s resources. This innovative technique not only benefits the environment but also delivers high-quality results, making it an ideal choice for both repair professionals and car owners seeking green alternatives.