PDR for aluminum panels offers a cost-effective, eco-friendly solution to repair damaged vehicle surfaces without repainting, preserving the original factory finish and extending the lifespan of lightweight, durable panels while reducing waste and energy consumption in auto repair.

“Discover the transformative power of PDR (Painted Metal Repair) and its unparalleled advantages for aluminum surfaces. This innovative technique offers a sustainable and cost-effective solution for restoring and enhancing aluminum panels.

Aluminum, known for its durability, benefits immensely from PDR, ensuring long-lasting protection. By minimizing environmental impact, this process not only conserves resources but also contributes to a greener future. Moreover, PDR revitalizes the aesthetics of aluminum, restoring its brilliance and adding a fresh, appealing finish. Explore these aspects in detail to understand why PDR for aluminum panels is a game-changer.”

- What is PDR and Why Aluminum Panels Benefit

- The Environmental Impact of PDR for Aluminum Surfaces

- Enhanced Aesthetics: PDR's Role in Brightening Aluminum Panels

What is PDR and Why Aluminum Panels Benefit

PDR stands for Paintless Dent Repair, a revolutionary technique that has transformed the automotive industry, especially when it comes to repairing aluminum panels. This method is all about restoring dented or damaged surfaces back to their original state without the need for traditional painting or auto glass replacement. By using specialized tools and techniques, PDR effectively removes dents and dings from aluminum bodywork, ensuring a flawless finish.

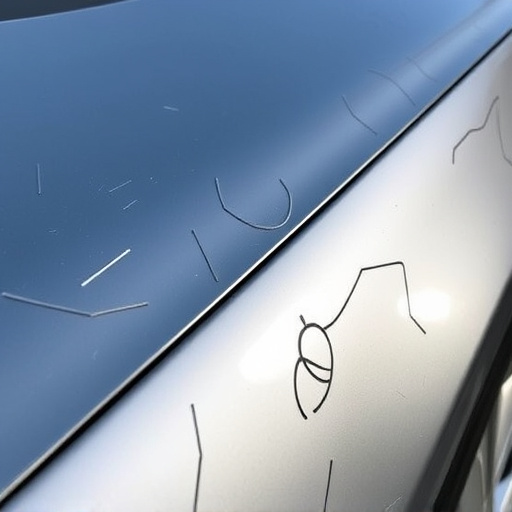

Aluminum panels benefit immensely from PDR due to their unique properties. Unlike other materials, aluminum is lightweight and highly recyclable, making it a popular choice in modern vehicle construction. However, its soft nature makes it susceptible to dents and scratches. PDR offers a cost-effective solution for bumper repair and fender repair, preserving the integrity of the metal while maintaining its aesthetic appeal. This non-invasive approach not only saves time but also prevents potential issues that could arise from opening up the panel for conventional repairs, such as rust or weakened structural integrity.

The Environmental Impact of PDR for Aluminum Surfaces

PDR (Paintless Dent Repair) for aluminum surfaces offers a sustainable solution with significant environmental benefits compared to traditional auto painting and car bodywork methods. This non-invasive approach minimizes waste generation, as it doesn’t require the use of harmful solvents or extensive primer and paint applications. By preserving the original factory finish on aluminum panels, PDR reduces the demand for new raw materials, lowering the carbon footprint associated with manufacturing new components.

Moreover, PDR is particularly advantageous for collision centers dealing with aluminum car bodies. It allows them to restore damaged aluminum surfaces to their original condition, extending the lifespan of these lightweight, durable panels. This process conserves resources and reduces the energy consumption typically associated with auto painting, making it a more eco-friendly option in the ever-evolving landscape of automotive repair and customization.

Enhanced Aesthetics: PDR's Role in Brightening Aluminum Panels

Aluminum panels, popular in automotive manufacturing due to their lightweight and corrosion-resistant properties, can sometimes suffer from dullness or imperfections post-production. This is where Paintless Dent Repair (PDR) steps in as a game-changer. PDR is an innovative car collision repair technique that enhances the aesthetics of aluminum surfaces without the need for repainting. By skillfully manipulating the metal, skilled technicians can brighten and restore panels to their original sparkle, eliminating unsightly dents and scratches.

Unlike traditional vehicle dent repair methods, PDR for aluminum panels is a non-invasive process. It involves using specialized tools to gently work around the damaged area, allowing the natural metal finish to be revived. This not only saves time and money compared to conventional collision repair but also preserves the original factory paint job. The result? A stunning, seamless finish that showcases the brilliance of the aluminum itself, making it a top choice for both professionals and car owners seeking an efficient solution for their dented or scratched aluminum panels.

PDR (Paintless Dent Repair) offers a multitude of benefits for aluminum surfaces, from environmental sustainability to enhanced aesthetics. By utilizing advanced techniques to remove dents and scratches without painting, PDR preserves the original finish of aluminum panels, ensuring they maintain their vibrant appearance. Moreover, this method reduces waste and minimizes the carbon footprint associated with traditional repair methods, making it an eco-friendly choice. In conclusion, adopting PDR for aluminum panels is a smart, sustainable, and aesthetically pleasing solution that benefits both businesses and the environment.