PDR for aluminum panels is a cutting-edge, non-invasive technique repairing dents and scratches without damaging the original finish, preserving vehicle aesthetics and value, offering precise manipulation, reduced costs and environmental impact compared to traditional methods, and maintaining resale value. Technicians assess damage, use specialized tools to manipulate metal behind the panel, and perform final inspections for seamless restoration.

In the automotive and industrial sectors, maintaining paint quality on aluminum panels is paramount. Enter PDR (Paint Damage Repair) – a gentle restoration technique that preserves the integrity of existing paint while eliminating scratches and dents. This article delves into the unique benefits of PDR specifically tailored for aluminum panels, outlining its step-by-step process to ensure optimal paint retention. Discover how PDR offers an efficient, cost-effective solution for revitalizing these surfaces.

- Understanding PDR: A Gentle Restoration Technique

- Benefits of PDR for Aluminum Panels' Paint

- Step-by-Step: The PDR Process on Aluminum Surfaces

Understanding PDR: A Gentle Restoration Technique

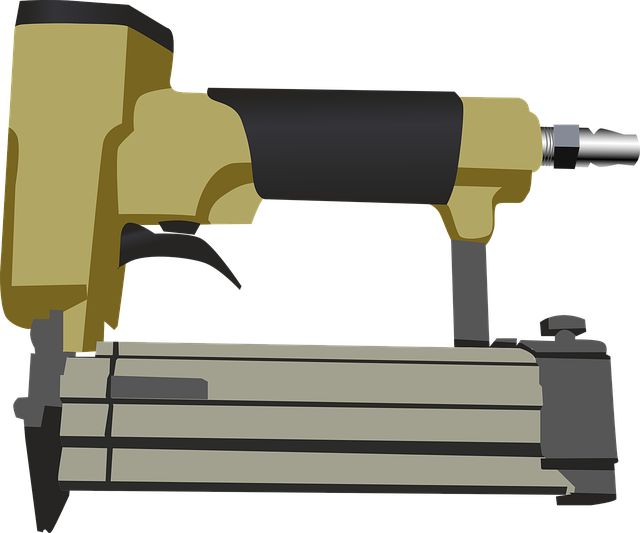

PDR, or Paintless Damage Repair, is a revolutionary technique that has transformed the way we restore vehicles, particularly aluminum panels. Unlike traditional car collision repair methods that often involve sandblasting and repainting, PDR for aluminum panels offers a gentle approach to damage restoration. This non-invasive method utilizes specialized tools and techniques to gently work on the exterior of a vehicle, repairing dents, scratches, and other types of paint imperfections without affecting the original finish.

By employing PDR, professionals can effectively restore car bodies to their pre-accident condition, maintaining the integrity and quality of the paintwork. This is especially beneficial for aluminum panels, which are known for their durability but also require meticulous care during repair processes. The technique has gained immense popularity due to its ability to provide a flawless finish, preserving the vehicle’s overall aesthetics and value, all while minimizing downtime associated with conventional car restoration methods.

Benefits of PDR for Aluminum Panels' Paint

PDR for aluminum panels offers several significant advantages when it comes to maintaining and repairing the paint quality of vehicles. Unlike traditional car repair shop methods that can be labor-intensive and time-consuming, PDR is a specialized technique designed to restore damaged surfaces without affecting the surrounding paintwork. This makes it ideal for vehicle collision repair, ensuring that even after a mishap, the vehicle’s original finish can be preserved.

The benefits extend beyond just aesthetics; PDR for aluminum panels enhances the structural integrity of the car body by gently manipulating and realigning dented areas, without the need for sandblasting or repainting. This not only reduces costs for both owners and repair shops but also minimizes the environmental impact associated with vehicle paint repair processes. By preserving the original paint job, PDR helps maintain the car’s resale value, making it a smart choice for anyone looking to keep their vehicle in top condition.

Step-by-Step: The PDR Process on Aluminum Surfaces

The Process of PDR (Paintless Dent Repair) for aluminum panels is a meticulous art that ensures the maintenance of paint quality on automotive surfaces. It begins with the assessment of the damage, where technicians carefully inspect the dent or blemish, determining its size, depth, and location. This step is crucial as it dictates the approach to follow.

Next, specialized tools are employed to access and manipulate the dent from behind the panel. Using a combination of precision and expertise, the PDR technician will gently work on realigning the metal, pushing and pulling it back into its original form while ensuring the paint remains intact. This process avoids any damage or chipping, preserving the panel’s aesthetic appeal. Once the dent is removed, a final inspection ensures the panel is restored to its seamless, factory-like condition, ready for display at your local auto collision center or car dent repair shop.

PDR for aluminum panels has emerged as a game-changer in vehicle paint restoration. By gently removing damaged or faded paint without compromising the original finish, this technique maintains the integrity and quality of the paint job. Whether it’s for minor scratches or significant dents, PDR offers a cost-effective and efficient solution. Through meticulous steps involving specialized tools and expert techniques, the process restores aluminum surfaces to their pristine condition, ensuring a long-lasting, vibrant finish that stands out in today’s market.